BEEZ INDUSTRIES MOROCCO

The world is on the cusp of a technological revolution that promises to

fundamentally transform industries, economies, and societies. It's called

Industry 4.0, and it represents the fusion of the physical, digital, and

biological worlds in a way that will impact all disciplines, industries, and

economies.

The Fourth Industrial Revolution

Industry 4.0, also known as the Fourth Industrial Revolution, builds on

the legacy of previous industrial revolutions. The First Industrial Revolution

saw the mechanization of production through water and steam power, followed by

the Second Industrial Revolution that brought about mass production through

electricity and assembly lines. The Third Industrial Revolution introduced

automation, electronics, and information technology. Now, we are entering the

Fourth Industrial Revolution, where cyber-physical systems, the Internet of

Things (IoT), artificial intelligence (AI), and big data are taking center

stage.

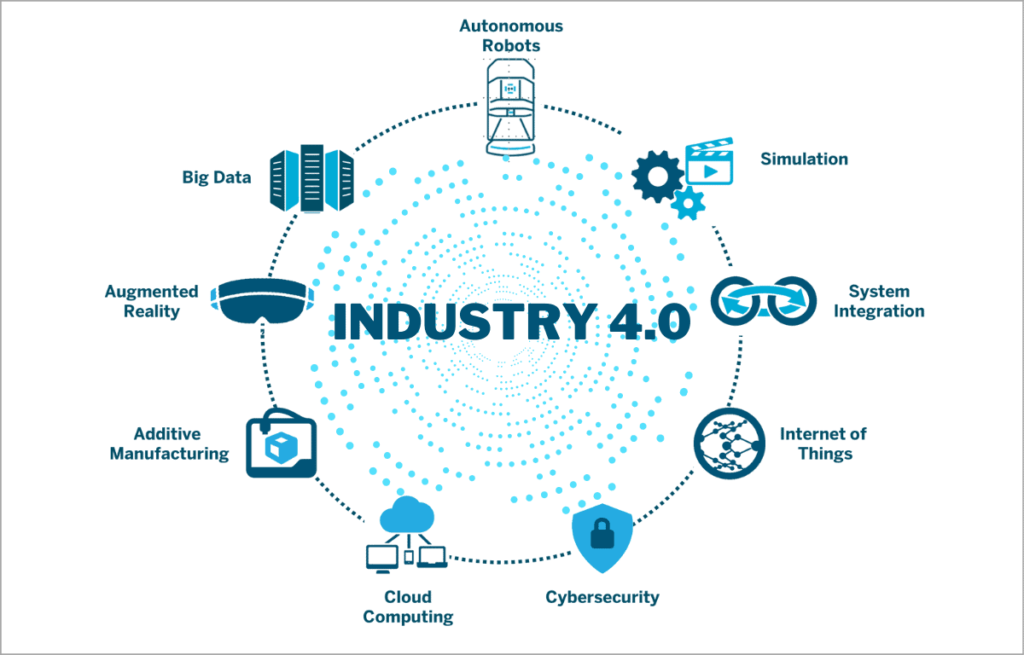

Key Pillars of Industry 4.0

IoT and Connectivity: In Industry 4.0, devices and machines are equipped

with sensors and connected to the internet. This enables real-time data

exchange, monitoring, and control, creating smart factories and supply chains.

Big Data and Analytics: The sheer volume of data generated by IoT

devices is immense. Big data analytics and machine learning allow us to derive

valuable insights from this data, leading to improved decision-making,

predictive maintenance, and increased efficiency.

Artificial Intelligence and Machine Learning: AI is at the heart of

Industry 4.0. It's used for predictive analysis, quality control, and

automation. AI-driven robots and autonomous systems are increasingly being used

in manufacturing processes.

Automation and Robotics: Advanced robotics and automation technologies

are being integrated into production lines. These robots can work alongside

humans, performing tasks with precision and speed.

3D Printing: Additive manufacturing or 3D printing is revolutionizing

prototyping and customization. It allows for rapid, cost-effective production

of complex parts.

Cloud Computing: The cloud is the backbone of Industry 4.0. It enables

remote access to data, software, and processing power, making it easier for

companies to scale and adopt new technologies.

Impact on Manufacturing

Industry 4.0 is reshaping manufacturing in profound ways:

Smart Factories: Factories are becoming smarter, with machines that

communicate with each other. This enables adaptive and flexible manufacturing

processes.

Predictive Maintenance: Equipment and machinery can predict when they

will need maintenance, reducing downtime and costs.

Customization: Mass production is giving way to mass customization.

Products can be tailored to individual customer needs.

Sustainability: Industry 4.0 can help reduce waste and energy

consumption, making manufacturing more sustainable.

Beyond Manufacturing

Industry 4.0's impact goes well beyond manufacturing:

Supply Chain Management: Improved visibility and control over the supply

chain enhance efficiency and reduce waste.

Healthcare: Telemedicine, wearable devices, and AI-driven diagnostics

are transforming healthcare delivery.

Smart Cities: IoT and data analytics can improve traffic management,

energy use, and public services.

Education: Personalized learning and online education are becoming more

effective with AI.

Energy: Smart grids and IoT help optimize energy distribution and

consumption.

Challenges and Opportunities

While Industry 4.0 presents immense opportunities, it also poses

challenges. Concerns about data security, privacy, and the impact on employment

need to be addressed. Companies and governments must adapt to stay competitive.

In conclusion, Industry 4.0 is ushering in a new era of innovation and

productivity. It's changing the way we manufacture, work, and live. Embracing

this revolution and managing its challenges is key to a prosperous and

sustainable future. Industry 4.0 is not just the future; it's the present, and

it's here to stay.

0 Commentaires